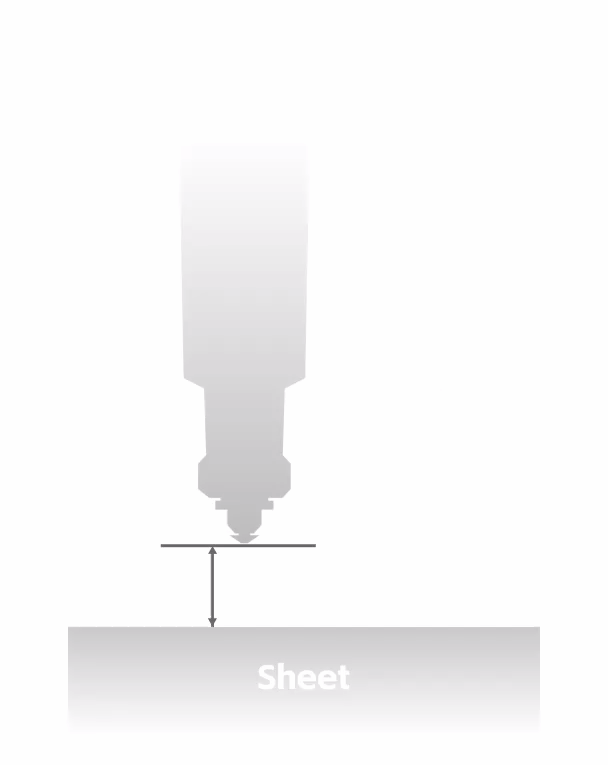

In the process of processing, in order to ensure stable cutting, we hope the distance between the nozzle and the plate is kept constant.

So how does the system determine the relative distance between the plate and the cutting head?

Typically, the cutting head's base incorporates a capacitive sensor. When the distance between the nozzle and the workpiece changes, the capacitance value also varies.

In the calibration process, the cutting head first probes the plate, with the height marked as 0, then moves upward to record the corresponding capacitance value based on the mechanical transmission distance, forming a capacitance-height curve. In actual processing, the current height can be calculated using the real-time capacitance value.

The capacitance reading is different after each replacement of the nozzle, ceramic ring and amplifier, so it is necessary to recalibrate before cutting.

Capacitor calibration in the super control system is straightforward. First, position the cutting head on the sheet metal surface, then click the calibration button in the CNC menu bar, select capacitor calibration, and click the button. The system will automatically complete the calibration.