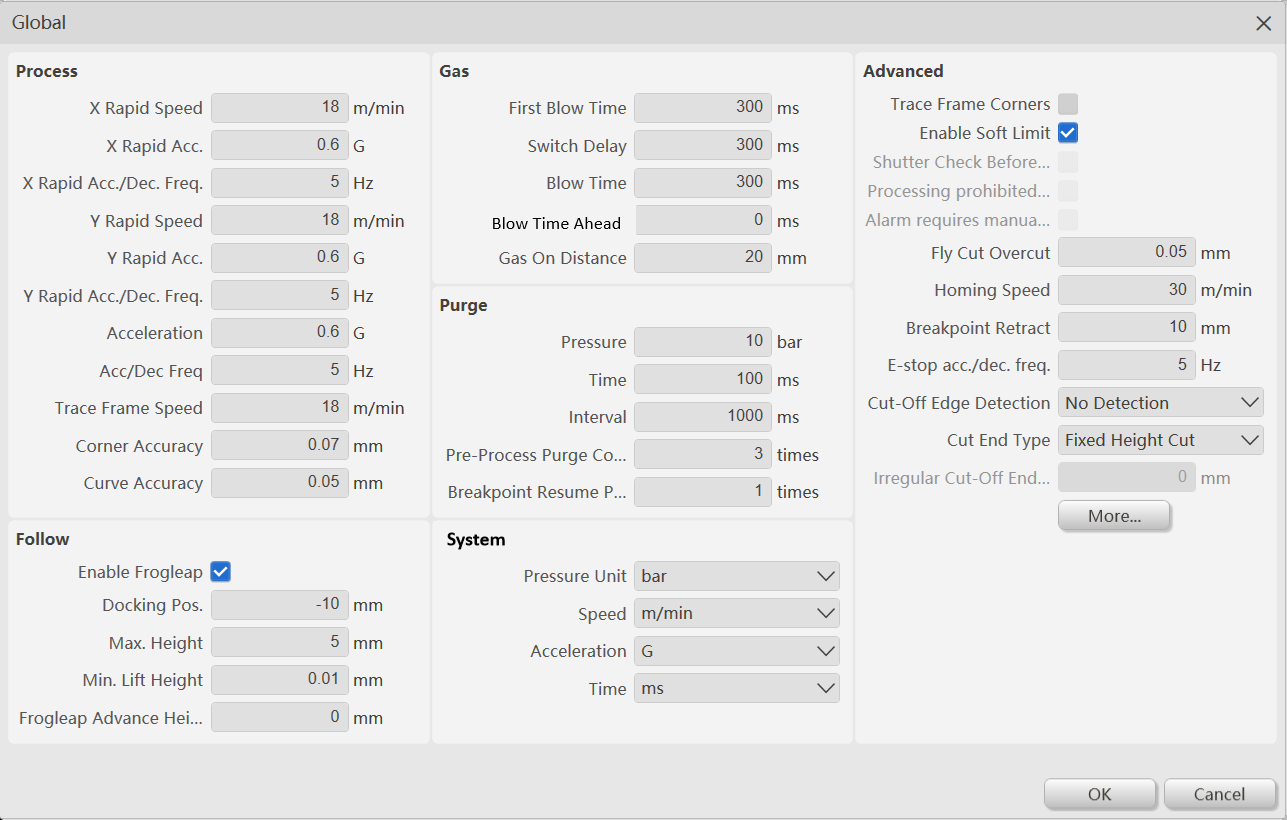

In the laser cutting process, the main function of blowing time is to improve the blowing quality. The mainstream control system has four blowing time parameters in the global parameters: first blow time, air change delay, blowing delay and early opening time.

The first blowing time and blowing time are both the blowing time before the opening.

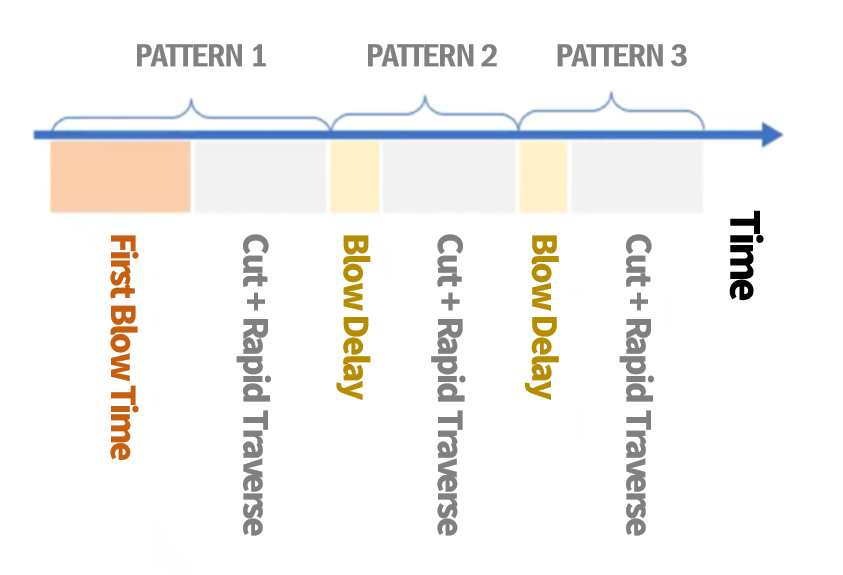

When there are multiple patterns on the processed whole board, the difference between the first blow time and blow delay is that the first blow delay only controls the blowing time before cutting the first pattern, while blow delay refers to the blow time before cutting each pattern.

The initial gas injection delay is typically set to a longer duration, such as 2000 milliseconds. This is because when the cutting machine has not been used for an extended period, the cutting head requires time to fill with high-purity gas, and the gas becomes more abundant during the cutting process.

Meanwhile, the air-blowing delay shouldn't be set too short, 500 milliseconds is recommended. Setting it too short may cause issues like premature light emission due to insufficient pressure or damage to the protective lens.

Gas exchange delay refers to the time required to fully purge the previous gas during gas switching. For example, when cutting thick plates, oxygen is used for piercing and nitrogen for cutting. If the oxygen is not completely purged during the switch, it may cause the cross-section to turn yellow.

Early gas activation refers to initiating gas flow before the cutting head's complete displacement, thereby eliminating the need to wait until it reaches the cutting starting point.