In laser cutting, precise adjustment of the light emission timing parameter is critical. It not only affects cutting quality but also directly impacts equipment lifespan. Incorrect delay settings may cause slag splashing to damage lenses, irregular cutting starts, or even material overburning and deformation.

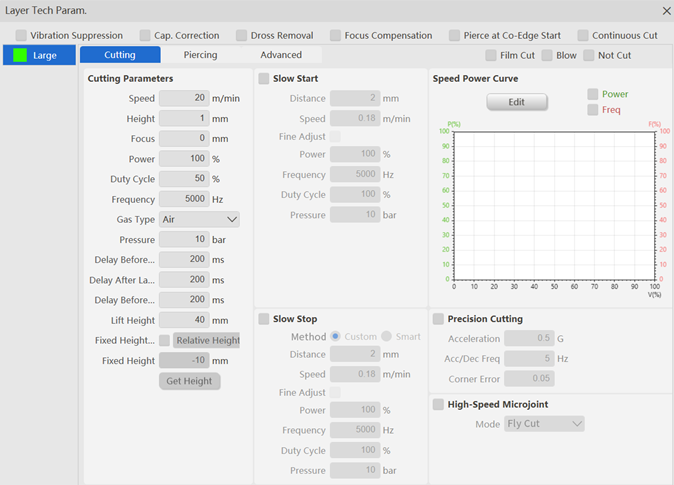

The mainstream control system has three time parameters in the process layer window: delay before light opening, delay after light opening and delay before light closing.

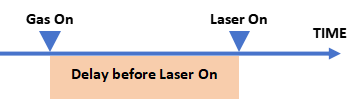

Delay before Laser On refers to the time before the actual laser firing when the gas is blown. Since the speed of light is much faster than the gas release speed, to prevent the molten slag from damaging the lens when the gas is blown out, the gas is usually blown before the processing begins.

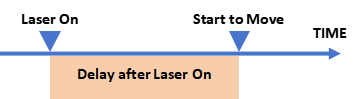

Delay after Laser On refers to the duration the cutting head waits before starting movement. This parameter is typically applied to non-perforated sheet materials, where the system first performs laser firing to complete preheating and ensures the initial cut is fully penetrated before moving.

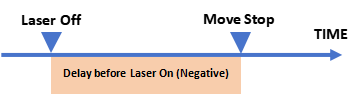

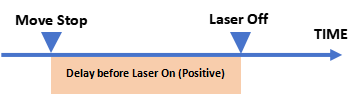

Delay before Laser On refers to the duration after the cutting head completes its path and stops moving before the laser is turned off. This parameter ensures the laser remains active for an extended period when cutting thick plates, particularly when the cutting end point is not fully reached below the trailing edge, to guarantee complete penetration.

For example, if a burn or dent appears at the end of a cut part, the issue is caused by the part falling off due to gravity while the laser continues to emit light. To resolve this, simply set the Delay before Laser On to a negative value and turn off the laser early.