Speed: Not Faster is Always Better

The "speed" in laser cutting usually refers to the maximum cutting speed, but the speed is significantly reduced at the small holes and corners to avoid mechanical vibration and loss of precision.

Key principles for speed settings:

1. The thicker the sheet, the slower the speed

- If the cutting speed is too high, the cutting will not be thorough, the cutting surface will be slanted, and the lower part will be melted.

- Reason: The thick plate requires a longer energy exposure time. Otherwise, the bottom will lack sufficient energy.

2. The thin plate can be cut at high speed

- When the thickness is less than 3mm, the speed can be increased to 80-100%.

- Match the appropriate power to prevent burnout

Focus: Key Factors Affecting Cutting Quality

The focal point determines the energy density distribution of the laser beam on the cutting surface, which directly affects the cutting quality. During calibration, the system is usually first locked at the zero focal point before adjustments are made.

| Focus Point Type | Applicable Scene | Matters Need Attention |

|---|---|---|

| Zero Focus (focus on the surface of the sheet) | Precision cutting of sheet metal with thickness of 1mm or less | Basic settings, typically using the perforation leveling as the reference |

| Positive Focus (focus above the sheet) | Oxygen-cured carbon steel | Insufficient energy at the bottom may cause the cutter to fail to penetrate and leave slag behind The nozzle is getting hotter |

| Negative Focus (focus located inside or below the sheet) | Nitrogen/air cut stainless steel or aluminum sheet | Narrower slit, difficult slag discharge May cause slag adhesion |

Power: The Relationship between Peak Power, Duty Cycle and Frequency

1. Frequency: Number of laser pulses per second

For fiber laser, laser firing is not continuous, but high frequency and repeated action of light emission and extinction (Pulsed, one irradiation process is one pulse).

For example :

5000Hz indicates 5000 laser switches per second, with each light emission and extinction cycle lasting 1/5000=0.0002 seconds.

Furthermore, the higher the frequency, the shorter the light emission and the smaller the heat-affected zone, which makes it suitable for fine cutting.

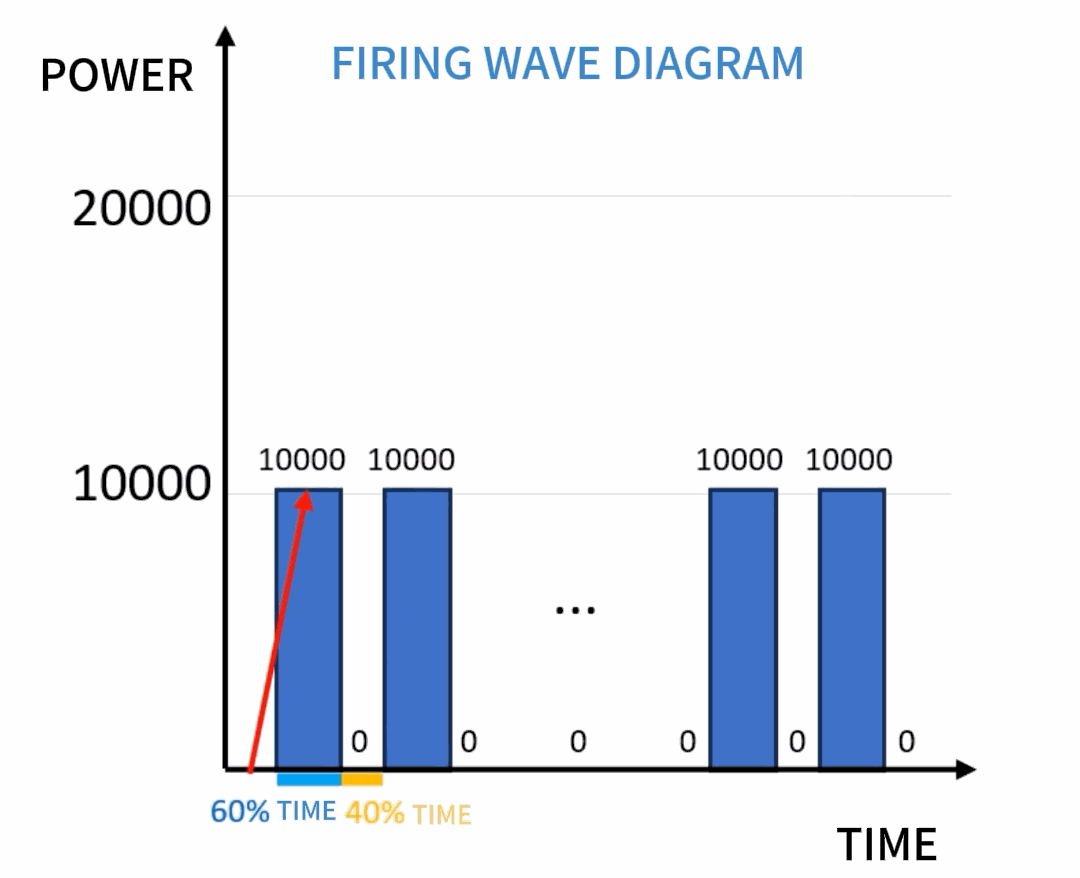

2. The duty cycle is divided into two stages: light emission and light extinction. The duty cycle is the ratio of the light emission time to the rest time.

Based on the frequency, a 60% duty cycle means the pulse starts with 0.00012 seconds of light (0.0002 seconds × 60%) followed by 0.00008 seconds of light-off (0.0002 seconds × 40%). This completes one emission cycle, while the second emission begins, repeating in a loop.

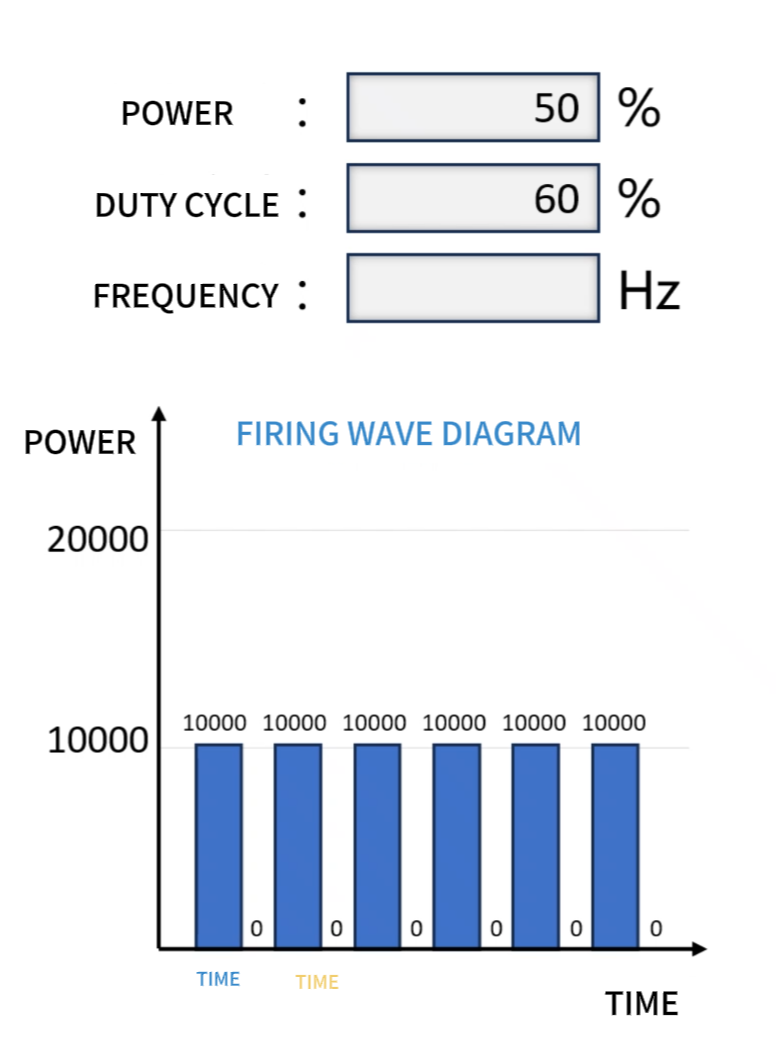

3. Peak power: Sets the upper limit of laser power during actual cutting, with the laser device's full power as 100%.

For example :

Set to 50% to achieve an actual output of 20,000 × 50% = 10,000W

Process Strategies for Different Scenarios

| Scene | Cutting strategy |

|---|---|

| Devices with 1500W or less | Peak power 100% + Duty cycle 100% + Frequency 5000Hz |

| Thin plate cutting for equipment with power above 3000W | To reduce thermal damage, adjust power and duty cycle |

| Thick plate cutting | Slow speed leads to heat accumulation, and the laser power should also be reduced |

| Air-cured aluminum plate / thick iron plate | Reduce the duty cycle and frequency |